How does the upfront cost of a heat recovery evaporator compare to other deslination technologies available on the market today?

-

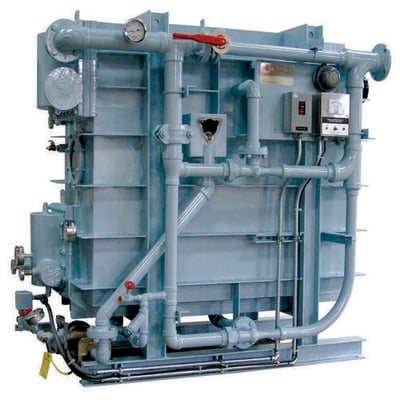

When comparing one of our units to an RO unit of similar high quality, the upfront capital costs are comparable. The same is true when comparing a Maxim evaporator to waste heat units offered by other manufacturers. When considering long term economics, significantly longer equipment life and low operating costs yield an excellent return-on-investment.